-

Hotline : +84 981 282 028

- vyan.company@gmail.com

Zinc Alloy

Price:

ContactPeople are viewing this right now

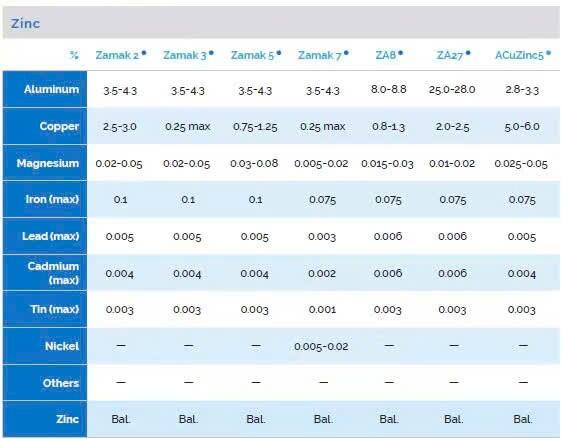

There are various types of zinc alloys with different compositions and properties, suitable for many industrial applications. Here are some common types:

Zamak 3: Contains about 4% aluminum and 0.04% magnesium. It is the most widely used zinc alloy, offering high durability and excellent corrosion resistance. Commonly used in the production of door locks, furniture accessories, and machine components.

Zamak 5: Similar to Zamak 3 but with an additional 1% copper, which increases hardness and strength. This alloy is often used in household appliances and interior decoration.

Za-8: Contains 8% aluminum, 0.02% magnesium, and 1% copper. It is the only Za-series alloy that can be hot-chamber die-cast, making it suitable for high-strength products requiring good pressure-tightness.

Za-27: Contains 27% aluminum, 0.015% magnesium, and 2% copper. It has the highest melting point and excellent load-bearing capacity, commonly used in engine components, pumps, and valves.

Zinc alloys play an essential role in producing door handles, locks, hinges, die-casting accessories, and various industrial products.