-

Hotline : +84 981 282 028

- vyan.company@gmail.com

Vietnam's Clinker

Price:

ContactPeople are viewing this right now

Clinker is a product obtained from the calcination process of a mixture of limestone and clay, along with some additional materials such as iron ore, sand, bauxite, etc., at a temperature of 1,450°C.

Its chemical composition primarily consists of oxides, including calcium oxide (CaO) from limestone, silicon dioxide (SiO₂), iron oxide (Fe₂O₃), and aluminum oxide (Al₂O₃) from clay, with additional minerals used as supplementary additives.

This material plays a crucial role in cement production, influencing the strength, durability, and bonding properties of the final product

During calcination at 1,450°C, various oxides react with each other to form the four main minerals in clinker:

C3S (3CaO·SiO₂) – Tricalcium silicate, responsible for early strength development in cement.

C2S (2CaO·SiO₂) – Dicalcium silicate, contributing to long-term strength.

C3A (3CaO·Al₂O₃) – Tricalcium aluminate, affecting setting time and early hydration.

C4AF (4CaO·Al₂O₃·Fe₂O₃) – Tetracalcium aluminoferrite, improving color, strength, and heat resistance.

These minerals have a non-uniform crystalline structure, influencing the physical and chemical properties of clinker, and ultimately determining the performance and characteristics of cement.

Clinker Formation Process:

Clinker Formation Process

Once we understand what clinker is, we can explore how it is formed and prepared for use in cement production.

To be usable, clinker must be ground and mixed with other components to produce cement, a crucial binding material in construction.

Formation Process

Cooling: After being heated in a rotary kiln at 1,450°C, clinker is rapidly cooled to stabilize its crystalline structure.

Grinding & Mixing: The cooled clinker is passed through grinding mills to ensure it does not form lumps and maintains its bonding capability. During this stage, calcium sulfate and limestone are added to improve cement properties.

Final Processing: The grinding duration depends on customer requirements but generally does not significantly impact product quality.

Beyond bagged cement products distributed in the market, ground clinker is also used to create ready-mix concrete, which speeds up construction work. When using cement, proper water mixing ratios must be maintained—neither too dry nor overly wet—to ensure optimal bonding strength.

Summary

The clinker production process consists of three essential stages:

Calcination in the kiln

Cooling

Grinding and mixing with additives to produce the final cement product.

This systematic approach guarantees high-quality cement, contributing to strong and durable construction materials.

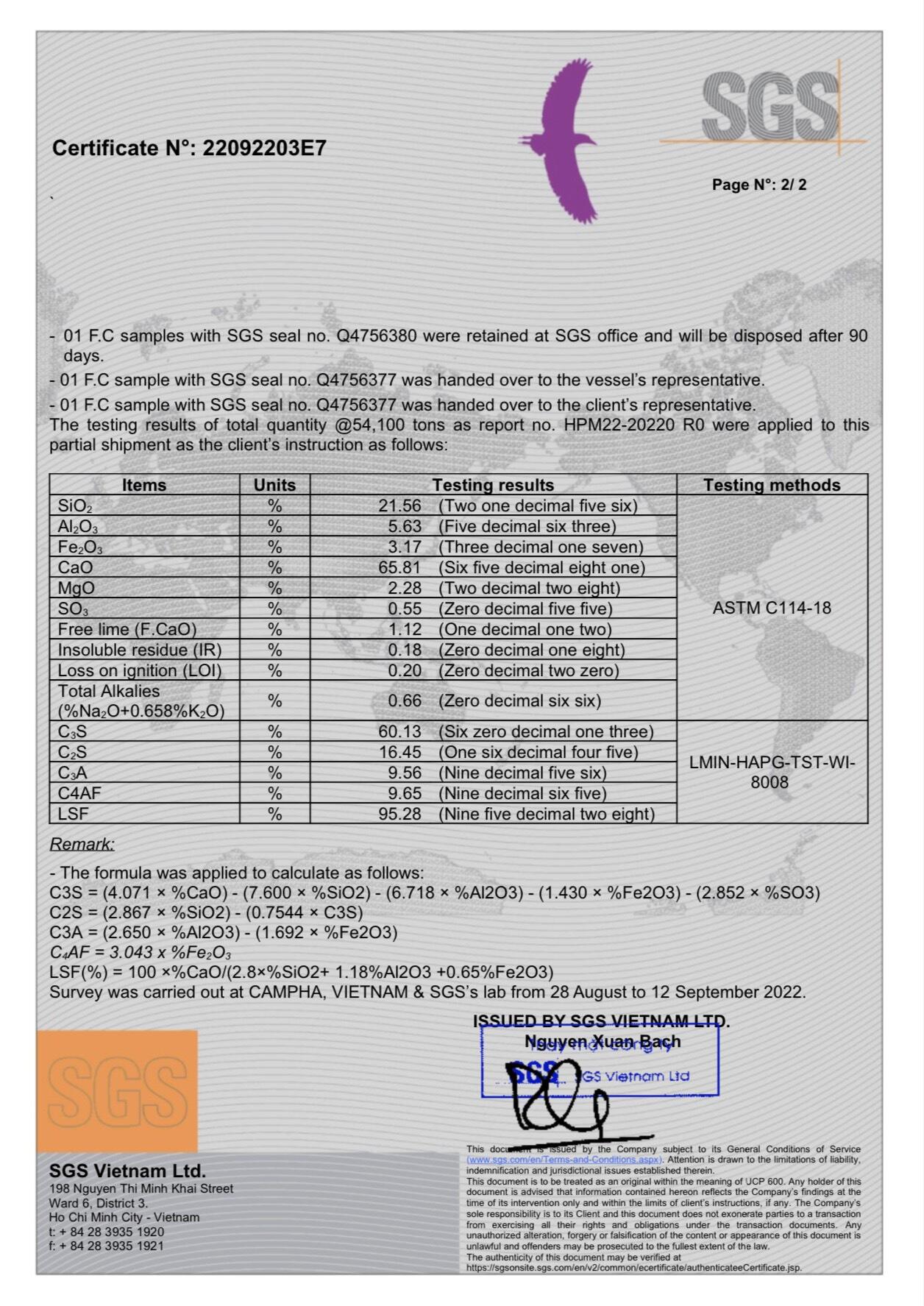

Clinker Specifications:

Clinker is the primary material for cement production, with essential chemical composition and physical properties that determine product quality. Below are common technical specifications of clinker:

Chemical Composition

CaO (Calcium Oxide): 62 - 68%

SiO₂ (Silicon Dioxide): 21 - 24%

Al₂O₃ (Aluminum Oxide): 4 - 8%

Fe₂O₃ (Iron Oxide): 2 - 5%

MgO (Magnesium Oxide): <5%

K₂O, Na₂O (Total Alkali Content): <2%

Physical Properties

Density: 3.0 - 3.2 g/cm³

Fineness: 2800 - 3500 cm²/g (Blaine method)

Burning Temperature: ~1,450°C

Color: Reddish-brown or grayish-green

Applications

Clinker is used to produce Portland cement, white cement, sulfate-resistant cement, and ready-mix concrete. The quality of clinker directly affects cement strength, bonding ability, and setting time.